Tool and Die

Done here – Done right

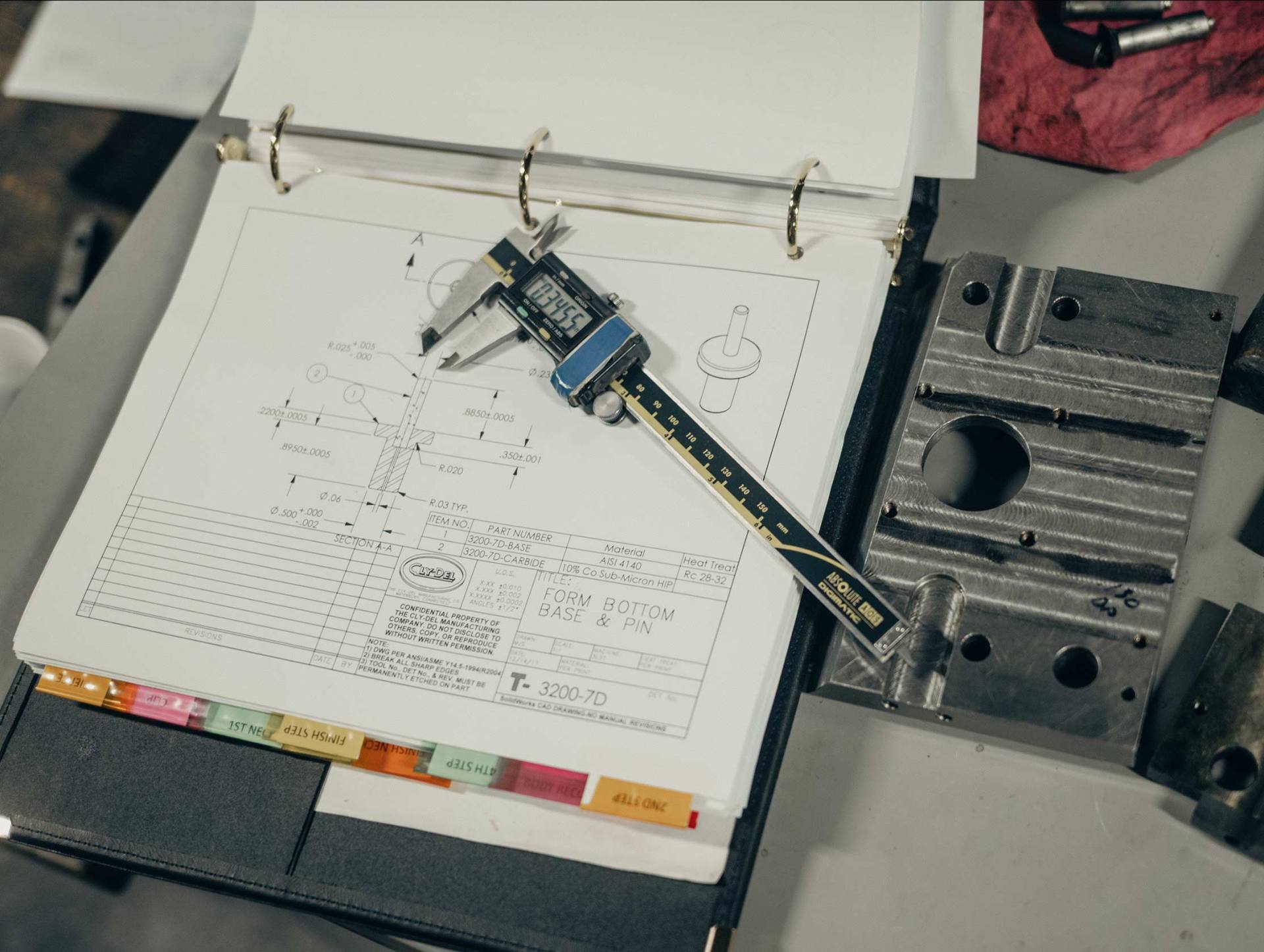

Cly-Del's team of celebrated journeyman toolmakers and engineers work in close collaboration to continuously expand the horizons of traditional tool design. We have complete tool building facilities for nearly all onsite production equipment to ensure all tooling meets and exceeds the demands set and repeatable precisions.

Precision in-house tooling

Through the utilization of advanced multi-station transfer and complex progressive tooling, we can provide added flexibility and economy to our customers. With expert knowledge of deep-drawing and progressive stamping, Cly-Del enables the development of technical solutions from a single source. Lastly, all of Cly-Del’s custom tooling is maintained for the life of the program.

Toolmaking equipment

Tools of the trade

Cly-Del’s tool rooms have a wide range of high precision machines for all applications including grinding, milling, hard turning, and electrical discharge machining (EDM). The ability to offer precision machining and grinding up to +/- 0.1 μm in Cly-Del’s climate controlled carbide, grinding, machining , and CNC departments ensures maximum precision.

For over 80 years we have developed, tested, and proven our own tooling. Using cutting-edge design and fabrication technology, Cly-Del can quickly and efficiently produce everything from prototypes and samples to durable tooling for full-scale production.